FUVPP Project Results

Flame Retarded Polypropylene - UL94 V0 Classification

Sustainable management of polymeric materials covers a wide range of key objectives promoting the principles of circular economy. In terms of materials eco-design, PolymeReEng group addresses issues regarding structure-properties relationships for biobased/biodegradable polymers such as PLA, PBS, including stabilization and durability. A new category of recyclable and functional polymers are the vitrimers that bridge the gap between thermosets and thermoplastics and provide a solution to the lack of recyclability in thermoset polymers. The PolymeREng group works on vitrimerization processes transforming commercial thermoplastics into dynamic chemically crosslinked structures through transesterification reactions in the solid ∕ melt state. The use of environmentally-friendly (green) additives such as halogen-free flame retardants and natural antioxidants derived from agro-food waste in polyolefins (PE, PP), gains the last years particular interest in the Groups research activities.

In terms of recycling, PolymeReEng group aims to develop appropriate upcycling routes depending on the extent of degradation of polymeric waste. Restabilization, chain extension and SSP processes are being evaluated for a number of polymers (eg PP, PBS, PLA) as approaches to safeguard against further degradation or even restore recyclate performance aiming at value-added new recycled products.

Panagiotopoulos Christos. Design and production of advanced polymeric materials via solid state polymerization. November 2020 – today.

Chronaki Konstantina. Solid state polymerization as a post-treatment tool for polymers upgrade. March 2017-today.

PRecycling: Plastics Recycling from and for home appliances, toys and textiles. Horizon Europe, 2022- 2026 (GA 101058670). Visit the Project Site.

BioICEP: Bio innovation of a circular economy for plastics. Horizon 2020, 2020-2024 (GA 870292). Visit the Project Site.

FUVPP: Flame-retarded and UV-Protected Polypropylene HFLS Pipes, (T2EDK-01466) EPAnEK 2014-2020, 2020-2023. Visit the Project Site (in greek).

Succivitr: Comprehending and controlling the dynamics of the adaptable network in biobased vitrimers. Design and production of advanced polymeric materials via solid state polymerization. November, PEVE0050, 2020 – today.

PRIORITY: COST action CA20101 - Plastics monitoring detection remediation recovery, 2021- 2025.

Flame Retarded Polypropylene - UL94 V0 Classification

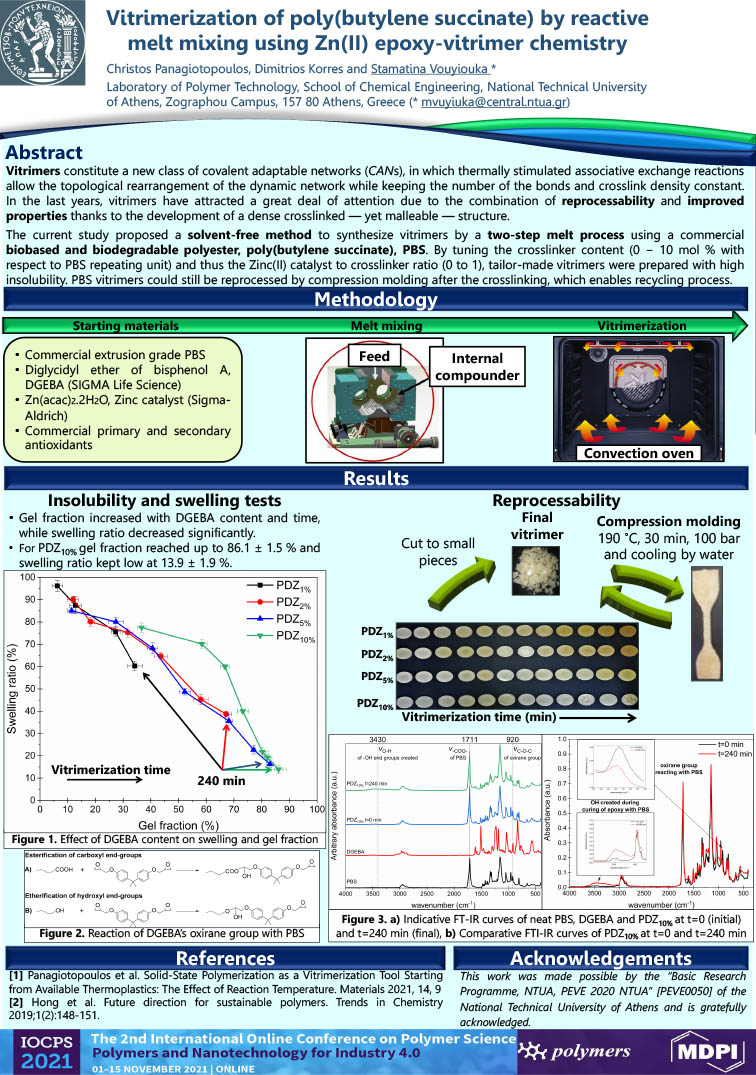

Panagiotopoulos Ch., Korres D.M., Vouyiouka S. Vitrimerization of poly(butylene succinate) by reactive melt mixing using Zn(II) epoxy-vitrimer chemistry, 2nd International Conference on Polymer Science (online), 1-15 November 2021. Download

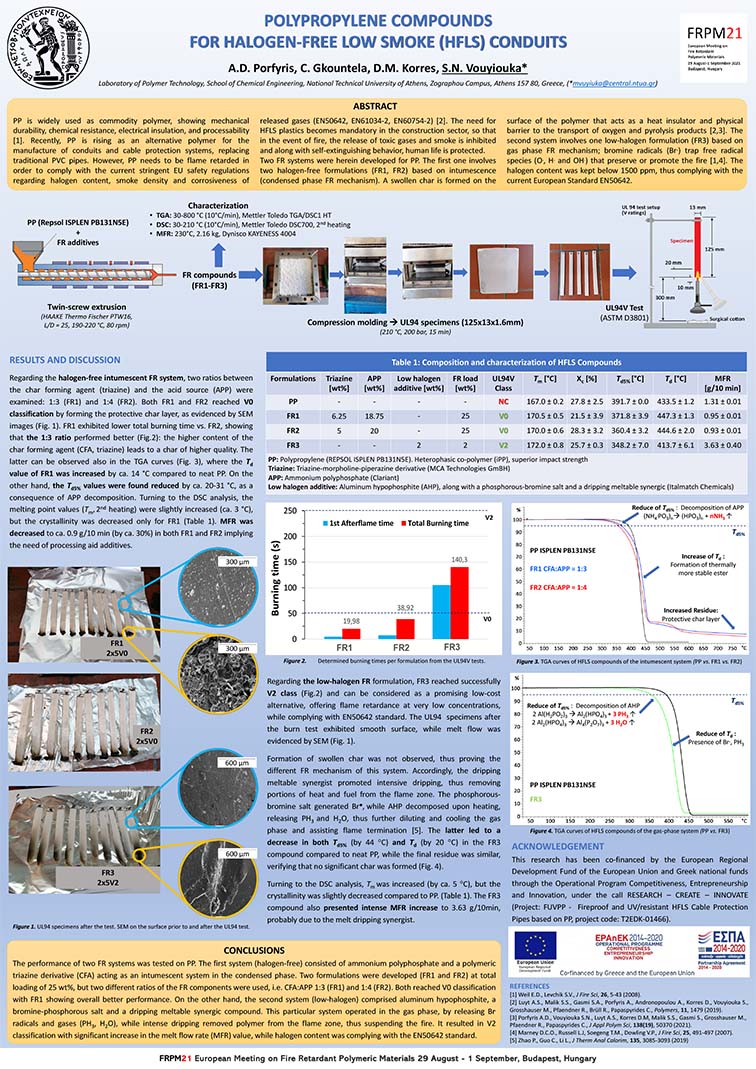

Porfyris Ath., Gkountela Chr., Korres D.M., Vouyiouka S. Polypropylene compounds for halogen-free low smoke (HFLS) conduits, FRPM21 - European Meeting on Fire Retardant Polymeric Materials, 29 August-1 September 2021. Download

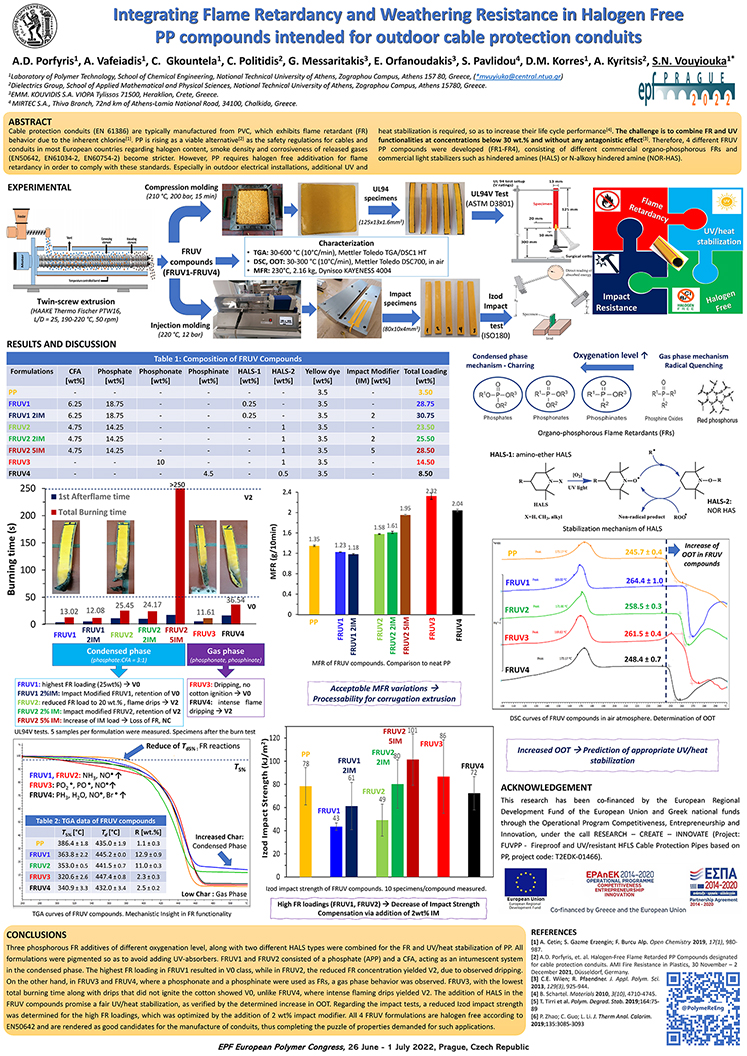

Porfyris Ath., Vafeiadis A., Gkountela Chr., Politidis Chr., Messaritakis G., Orfanoudakis Ep., Pavlidou S., Korres D.M., Kyritsis Ap., Vouyiouka S.N. Integrating Flame Retardancy and Weathering Resistance in Halogen Free PP compounds intended for outdoor cable protection conduits, EPF European Polymer Congress, 26 June - 1 July 2022, Prague, Czech Republic. Download